BioNTech IMFS Services

BioNTech IMFS has 20 years of experience in the translational field of cell and gene therapy. Having produced and released products for clinical trials in different clinical stages and different countries, we have an experienced team in house to meet your technology needs.

Technology Transfer

Independent of the status of your manufacturing process, if still in lab scale or already fully established, we at BioNTech IMFS would like to facilitate your product idea and technology to reach its full potential. We evaluate our customers’ process and provide targeted solutions for tech transfer and/or optimization, taking into account long-term projections and investments.

Due to the complex nature of transferring therapeutic processes, BioNTech IMFS has a technology transfer methodology and tools in place to ensure that your technology is transferred in an efficient and timely manner and with a particular attention to quality. If required, our team supports academic or early stage clients turning their cutting edge research into robust and reproducible manufacturing strategies that comply with GMP.

At BioNTech IMFS, a technology transfer project consists of 5 stages with clearly defined objectives and deliverables. We guide our clients through all stages from acquisition over information exchange to implementation followed by qualification/validation to finally routine performance.

Process Development

Pharmaceutical process development is a complex task, requiring customized solutions for each product. Successful process development requires an extensive understanding of the underlying science, product characteristics, state-of-the art technologies and a deep knowledge of the regulatory framework.

The BioNTech IMFS development and manufacturing team offers customers its proven expertise in GMP process development for different product types such as cells, viral vectors and mRNA. Our strength in process research and scale-up as well as experience with different products, coupled with our wide range of GMP capabilities allows us to deliver tailored and reliable solutions for our customers.

We select suitable technologies for the manufacturing process that will achieve sustainable production capacities, always with a view on the characteristics of your product while ensuring high quality and cost efficiency. From small scale to clinical trial support and, finally to commercial production we apply a lean manufacturing approach, combining the highest possible grade of process automation and/or closed systems with product-specific process steps and a comprehensive in-line QC panel.

To ensure that all relevant regulatory requirements are met, BioNTech IMFS QA is supporting every process development project.

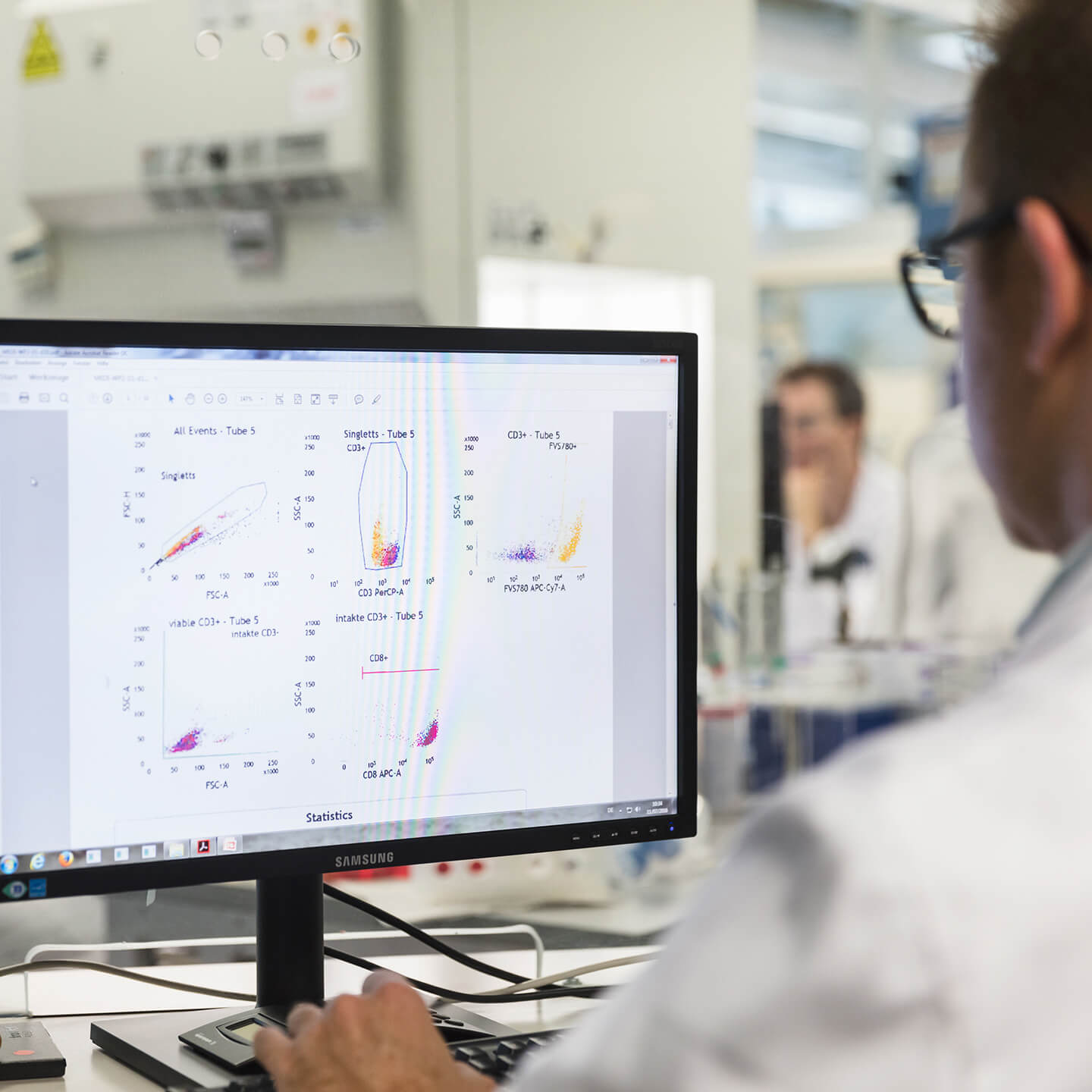

Assay Development

Fundamental to all aspects of drug development and manufacturing are robust analytical methods. Analytical methods require development, validation, and controls just as all other product and process development activities.

Our experienced analytical team offers customized assay development based on cell biology, virology, molecular biology, and microbiology technologies. Assay development services include assay design, assay validation, sample testing, and technology transfer. Alternatively, custom assays can be transferred from our clients, further optimized and validated.

Assays are developed and validated for bulk drug substance and final drug product, in-process analysis and lot release (safety, purity, potency, identity, and concentration/titer) according to ICH guidelines (specificity, linearity, LOD, LOQ, range, accuracy, and precision).

State-of-the-art equipment, cutting-edge technologies and experienced scientific staff ensure an efficient, high-quality and cost-effective assay development service.

GMP Manufacturing

The manufacturing of innovative cell and gene therapy or mRNA products is a complex and commonly customized process. BioNTech IMFS has been one of the pioneers in the cell and gene therapy manufacturing field. Already in 1999, BioNTech IMFS received a first manufacturing license (according to the German Medicines Act (AMG) for the production of stem cell products and in 2000 the permission to produce retroviral vectors and gene modified cells. Since then, the manufacturing license has been extended to cover a variety of customer products such as cellular products (naïve or gene modified; e.g. CAR-T cells), different retroviral vectors and IVT mRNA for in vivo and in vitro applications in immunotherapy.

In our state-of-the-art GMP facility (10 independent cleanroom suites), we have established robust manufacturing processes for a variety of different product types in different production systems (e.g. cell stacks, bags, bioreactors, robots) that can easily be adapted to our customers’ needs. Based on a broad spectrum of product, technology and regulatory expertise, we offer our clients a complete service spectrum from process development through clinical trial medication to in-market supply. BioNTech IMFS so far has produced >1000 products for cellular therapies, retroviral vectors as well as tumor vaccinations and has supplied numerous clinical trials worldwide.

GMP Quality Control

Development and manufacturing of an innovative cell or gene therapy product is a complex challenge and requires extensive Quality Control (QC) to ensure the quality and safety of the product as well as batch-to-batch consistency.

Our QC experts have the experience and technological expertise to develop, customize, validate and perform analytical methods required by our customers. We have established more than 50 assays for the characterization of cells, viral vectors and mRNAs to ensure and maintain consistency of our customers' final products. In order to cover additional tests that are not available at BioNTech IMFS, we have built a strong network of qualified analytical service partners.

Main QC functions:

- QC testing of incoming materials, API and DP

- Setting and justification of specifications

- Implementation and qualification/validation of analytical methods

- Management of reference standards, retention samples and assay cell banks

- Design and execution of stability programs

- Environmental monitoring

Quality Assurance & QP Release

At BioNTech IMFS, we want to provide our customers with the highest quality of services to meet their expectations. Since BioNTech IMFS obtained its first GMP ceritification in 1999, we have implemented a comprehensive process oriented Quality Management System. All relevant aspects of our organization, from premises and equipment to people and processes, are covered by our quality system.

Our Quality Assurance (QA) team provides directions throughout each customer project. This ensures that regulatory compliance to international guidelines and the highest quality and safety standards are at the center of each project. BioNTech IMFS QA oversees GMP production and quality systems and strives for continues improvement to meet our customer’s requirements within the regulatory framework.

BioNTech IMFS’ internal Qualified Persons (QP) are responsible for the final product release, according to regulatory guidelines.

Main Quality Assurance functions:

- Ensure overall compliance with GMP requirements

- GMP document management

- Qualification and validation

- Risk management

- Management of CAPA, deviations and change controls

- Audits and Inspections

- Communication with regulatory agencies

- Training